richardkwon

Regular Member-

Posts

69 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Articles

Videos

News & Articles

Everything posted by richardkwon

-

OK guys, it's been a year and a half since I've had to repair anything but now the outer tie rods are in need of replacement. Typical symptoms include popping over speed bumps, popping/click when turned all the way left or right and just a slight bit of wandering at highway speeds. Visual inspection shows the outer tie rod boots are now torn and compared to the new tie rods, there is some play. I've purchased new tie rods and was ready to go today thinking this would be an easy 1 hr job. Unfortunately, I can't seem to get the tie rod off. I loosened the nut that attaches to the rack. You have to hold the tie rod with a 21mm wrench and then using a 19mm wrench turn the nut right. Today I got as far as unscrewing the castle nut but could not take the nut totally off because the brake caliper was interfering and in the way so the nut will loosen almost to the end but cannot come off. This is seconday because once the tie rod is loosened, there should then be enough room to be able to take the nut completely off. My problem is the tie rod won't budge. I tried the hammer trick but it still won't move. Also, the tie rod castle nut is in the up position. Is this correct for this car? Most tie rods I've seen have the castle nut at the bottom. Any tips on how to remove the tie rod? The sledge hammer trick has worked for me in the past for other cars but not this one. Maybe I'm babying it too much and not hitting it hard enough? And in order to get the nut off, would turning the wheel all the way left or right allow room for the nut to come off? I figure if the tie rod becomes undone, there will be space for the nut to come off. Perhaps a trip to Autozone and the purchase of a Pitman puller is in order? The pictures attached are the passenger side.

-

Bra, da car be ee tin da oil cause of da valve cover gasket mon. And possibly da rear main seal ain't helpin ja nother. Check out my valve cover gasket tutorial any you should be fine bra.

-

You can disconnect the sensor and determine your fluid level the old fashion way or you can buy a new sensor. It's located at the bottom of the fluid reservoir. Sometimes the float gets stuck.

-

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

Landar thanks again for all your help. I always felt comfortable knowing you we're just a question away. It was like having a master technician standing right next to me at all times. Feel free to visit anytime. Thanks again! -

OK sorry, I thought you meant the actual pulley itself. Good luck and I'm sure the car will thank you for the new parts. :)

-

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

Got everything put together last night and the car runs great. When I first started the car, it started right up but shook a little bit and the "check VSV" light came on and white smoke was coming out of the exhaust so I cut the engine. I thought maybe I had not fully tightened the alternator bolts. You start trying to remember what you did. Did a recheck and yes the alternator bolts were fully tightened. Then I restarted the car. The VSV came on again and then went out after a few seconds. I think the initial shaking was due to the car sitting on jack stands at an angle and no oil in the front after having been completely drained of oil and the new oil control valves. Also when removing the valve covers I think some oil spilled onto the exhaust. After a couple of minutes of nice white smoke coming off the exhaust manifold, the oil burned off. Took the car for a spin and noticed a bit more power. Even got the tires to chirp in first gear. B) As for refilling the coolant it is a tedious job. First fill the reservoir. Then slowly fill the throttle body with 6 additional liters (1.5 gallons) of coolant. As the inlet opening is so small it takes awhile. When full, close the plug. I noticed that the new plug has thread sealant on the first few threads. Then run the engine for 10 minutes and keep topping off the reservoir. Keep checking for a few days as you will continually need to top off. As for installing the fan and the fan housing the best way is after installing the fan clutch, install the fan blade without the fan housing attached. Then install the radiator without the top clamps. This allows you to tilt the radiator towards the bumper and gives you plenty of room to install the fan housing. No more plastic edges to cut into your forearms! And this way it's so much easier to install the fan blade. I just used my left hand to hold the blade and tightened the screws with a wrench. When placing the air inlet housing back on make sure the long power steering air hose is routed underneath the housing and run along the fuel rail where the engine harness runs. In other words, the hose does not go over the air inlet rectangular box. Doing so will make the VBank cover not fit correctly. Another tip is when putting the water inlet (thermostat housing) back on, make sure the inlet tube and rubber o ring are inserted properly and fully. I thought I had everything inserted properly but later noticed the top of the mating surface was not flush and almost stripped my bolt. I am really happy and quite proud of myself. It took me a month but I basically did bits and pieces an hour here and there and really took my time. I also did my valve covers, cleaned out the throttle body and installed some additional parts so that took some more time. Another time eater was cleaning up everything. I'm a bit more anal than most. And I also had to wait on extra parts that needed to be replaced. The disassembly and assembly is literally a 2 hour job. I am very sure that if I had all the necessary parts I could do this job in a few hours now. What also adds time is the reading and researching and the fact that somewhere along the line you will get stumped and you may also break something. Just take it slow, label everything and take a lot of pictures. Be meticulous. There's nothing worse than figuring out if this is the right bolt. I had everything labeled and bagged and there were a couple of instances where it took me awhile to figure out which bolt or wire went where. I think if I had taken the car to a dealer they would have easily charged me $3,000 parts and labor for the timing belt, throttle body cleaning, spark plug change, replacing the radiator, crankshaft seal, various sensors, install of various new coolant and air hoses and new valve cover gaskets. Keep in mind I bought a bunch of new air and water hoses as well as new oil control valves, VSV, clips ,etc. The way I look at is with the money I saved doing my own labor I was able to get all these parts for free! And knowing I did the job means I did it right and not half assed or as my friend's dad used to say incorrectly "half fast". Tell me, how many mechanics would actually clean all your bolts and clean all the grease and dirt from your engine? All they care about is getting the parts replaced as quickly as possible. Also, don't fret too much about broken plastic clips. Our 1998-2000 model year cars are now over 15 years old. Thanks to that beautiful V-Bank cover, it helps to retain all that heat and cooks everything. Plastic and rubber becomes very hard and brittle. Even if you have the precision and delicate hand of an archaeologist, some plastic parts will still break. Don't worry. Just insert back, tape it, or use zip ties. Be careful of the wires and do not manhandle them. If you are really into fully restoring your car, the wiring harness (available as 3 separate pieces) can be purchased from the dealer for about $1400-2000. Installation is very easy. As for the timing belt itself I really believe the actual belt can last a long time. It's the water pump, worn pulleys, dirt, coolant and oil that cause the deterioration. The belt should rarely snap. It's the other items failing that cause the belt to fail. The water pump should always be replaced while you are there. If it seizes or starts leaking, the coolant can cause the belt to deteriorate in a jiffy. Thanks to Landar for all his help and his great tutorial which is the bible as far as tutorials go. But as good as Landar's tutorial is, I still had a lot of questions and confusion. Hopefully I have added some finer details and direction and clarity for the novices out there. And looking back, this entire job is very straightforward. There should not be a point or time where you should get "stuck" because there are no impossible angles or super tools that are needed. And thanks to CuriousB for his comments in the beginning. He really made me stop worrying that this was a difficult job especially regarding my jack stand question. I don't know why the hell I was worrying about having the car on jack stands. Oh wait, the reason was because I had thought that the car lifted at an angle would affect the timing. How stupid I was! So basically, if you've got 100K or so miles on your LS400, stop worrying and procrastinating and change out your belt and water pump yourself. You will save a lot of money doing it yourself and you will learn a lot about how great these cars are. -

Turn the bolts left (counterclockwise) to remove.

-

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

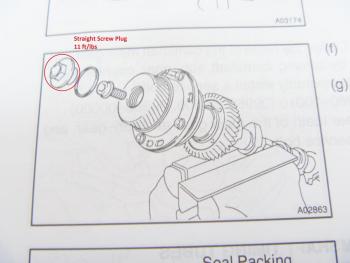

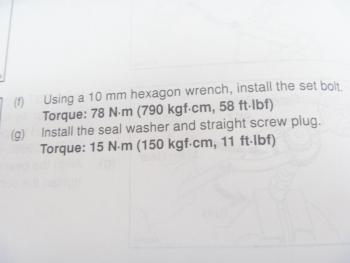

I checked the timing by making 4 full revolutions and everything lines up perfectly. Reading the service manual, there's a reason they indicate the use of the SST to hold/move the cams. The 19mm bolt (aka Straight Screw Plug) that I was using to move the cam backward is only torqued to 11 ft/lbs! No wonder why it kept coming loose. Before the screw plug, there is a seal washer. I guess it would have been nice to have an SST as it probably could have made things a lot easier. I looked online for this tool and there are varying costs ranging anywhere from $60 to $400, however, I don't think it is worth the cost. -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

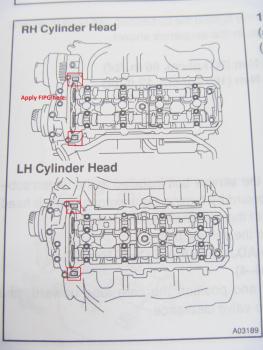

To install the VC gaskets, each rubber gasket will have several evenly distanced outer rib/nipples that run along the entire gasket and allows the gasket to stay in the VC valley when it is turned upside down to install. This is great so that you don't need to worry about constantly making sure the gasket does not fall out. No need to apply FIPG to the VC. Just apply the new FIPG to the 2 corners near the cam housing. See the pic. Press down and torque the bolts to 55 in/lbs by making several passes on each bolt. To torque the bottom bolts, I found an 18" extension with a swivel attached to the 10mm socket to be the most easy way to remove and tighten. Connect all the hoses and voila, no more VC leaks for hopefully several more years. -

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

I also had the joy of making my own seal tool from Home Depot. I think mine was a 2" diameter piece of PVC pipe with a screw in insert. Just buy 2 or 3 that fit together and you will have the proper length to tap it in. Total cost was about $5. You can always use a small hammer to tap in the seal also but make sure the seal is inserted evenly and flush. My seal went in just a hair more than flush. There will be a point where the seal will be driven to its maximum and you will know. Don't over do it and start crushing the seal. Make sure to coat the lip of the seal with a little bit of MP (multipurpose) grease. I had the hardest time determining what the hell the "lip" of a seal is. After much diligent research, it's the inner part of the seal folks. However, DO NOT grease or oil the outer part of the seal! I guess the reason I am putting so much emphasis on this little seal is twofold: First, it takes a lot of work to get to this sucker and you don't want to go through this entire process again just to replace this $8 seal. Second, if this seal starts leaking, the oil will get on to your timing belt and will destroy everything which is not good. -

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

And before I installed the new timing belt, I cleaned out the grooves in the timing gear pulley and the front and back. I also tried to clean as many grooves in the cams as I could. I used brake cleaner and a bunch of Qtips to clean out all the belt dust and dirt. -

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

OK got the dang thing on. Took me about 1/2 hour and was very easy actually. Most of the time was spent retorqueing the LH Cam bolt so that I could get some leverage to back the cam. So basically, when I initially removed the belt, only the RH Cam moved a few degrees. The LH Cam did not move at all. When I put the new belt on, I had the CR mark at the indentation on the timing gear pulley and the LH Cam arrow on the LH Cam. When trying to maneuver the belt on the RH Cam side, the LH Cam snap rolled a bit forward. And then it did it again. This is the reason for the 50 degrees. It buys you quite a bit of wriggle room. And it seems like the cams will snap and roll for no apparent reason. The goal with first placing the belt on the LH Cam is to get as much tension on the LH Cam belt side so that you can easily slip on the RH Cam belt side. To do this, you will need to put a 19mm socket on the cam bolt to get the LH Cam to move back or CCW with the goal of aligning the LH Cam arrow on the belt with the indentation on the LH Cam. However, this is also how the bolt becomes undone. My bolt kept coming loose so that I was not able to move the cam backwards. So I used my old timing belt, wrapped it around the cam, tightened the belt together with vise grips and then holding the belt tightly, retorqued the bolt as much as possible. The cam moved forward again a bit but it was nothing to worry about. The service manual mentions to rotate the LH Cam backward as much as possible to get the belt on this side tensioned as tight as possible. Doing this allows you to easily slip on the RH Cam side of the belt. There was plenty of slack so that I was able to easily slip the belt on. No crushed fingers between the cam gear and belt and I only had to rotate the RH Cam backwards a few notches. Everything is now aligned. I installed the tensioner last (not installing the tension initially gives you more slack when putting on the belt). Now it's on to rechecking the timing marks before pulling the pin. Also when initially placing the belt on, make sure the electrical wires and connectors on the LH Cam side are out of the way. Thanks Landar for your instructions. I think it's all downhill and easy street from here. -

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

Damn Landar, I'm sure glad you're here. I'll give it a shot tomorrow afternoon. I knew this was the part that I would get stumped. It's very frustrating because I'm constantly wondering if I'm turning the cams in the correct direction and what if I messed up the timing and so on. Thanks for the direction. -

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

Landar, I tried installing the timing belt today. I had the CR arrow exactly on the timing pulley indentation mark hole and the LH Cam arrow on the LH Cam. Then all of a sudden the LH Cam moved clockwise to the right and now the belt on this side is very loose. I tried to move it CCW to bring it back to 50 degrees and will come back a little bit but then the 19mm bolt becomes very loose. So of course, now the RH Cam side of the belt does not have enough slack to slip it onto the cam as there is too much slack on the LH Cam side of the belt. What am I doing wrong and how do I fix this? -

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

Yes I think at about 180K should be fine. -

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

To remove the seal, you can use either a seal removal tool (looks like a T shaped ice pick) or cut the inner part of the seal and then place a screwdriver and pry the seal out (just like the spark plug tube seals). Not wanting to gouge the metal, I first drilled a small hole and then tapped in a screw. Then using a pry bar, I popped the seal right out. My seal was not leaking and was in excellent shape although it was a bit harder than the replacement seal. The outer seal is a hard plastic rubber and the inner part is flexible rubber with a tiny inner metal spring coil. Mine had just a bit of oil on the bottom of the inside seal and I'm sure it would have lasted quite a bit longer. This is definitely a 200K replacement item imo and I would definitely recommend at every timing belt change. -

98 1uz-fe Timing Belt And Water Pump Replacement How_to

richardkwon replied to landar's topic in 90 - 00 Lexus LS400

For those of you wanting to remove your crankshaft front oil seal (or as Toyota calls it, the oil pump seal), the procedure is very simple. First you will need to remove the timing belt gear pulley. If your gear pulley is not rusted on to the crank, then you may be able to pry it out with 2 screwdrivers. I bought a pulley puller and had to buy 2 M6 hex bolts that are at least 65mm in length. You will also need some fairly large washers. Place the 2 bolts in the gear pulley holes and then pull it off the crankshaft. -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

Thanks CuriousB. The LS400 is truly a fantastically engineered car and well deserving of fresh VC gaskets! -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

Now, install a fresh new PCV valve and grommet. Taking the valve and grommet out requires a lot of muscle. Installing them takes the muscle of a gorilla and the intelligence of a human. Actually, it's not too bad and is definitely easier when the VC is off the cylinder head. First, remove the PCV valve separately and then the grommet. The grommet will be fairly hard due to age and heat. Using pliers, remove the PCV valve first. Then grab the grommet from the edge and remove it. It will take a bit of finagling and wriggling around before it finally pops out. If it is still hard to remove, you may want to cut a piece out first. Try not to drop it in the VC housing. To install, first assemble the PCV valve and grommet together. Then apply some soapy water to the grommet and then insert into the hole/housing. Believe me, it's not that easy. It took a lot of finger muscle to get it halfway in. And I could not use all my force for fear of breaking the plastic elbow piping. I had to resort to using a large plier to grab the edge of the grommet and use the spark plug tube hole for leverage. -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

To prepare the bolts for reinstallation, you will need to remove the grommets, which are now rock hard and no longer pliable. As the rubber has now turned to brittle plastic, they will no longer come off the bolt by hand. To remove, grab the grommet with some pliers and using a 10mm socket wrench, remove the grommet This is fairly tedious as there are 18 grommets. After the grommets are finally removed, clean all the bolts of oil and plastic debris using brake cleaner. Now as to why the VC bolts get so loose? Well, the bolt grommets are made of soft rubber. Put 100,000 miles of intense heat and 15 years of age and guess what? You get nicely cooked grommets that turn into rocks! Then put a little oil on them from the leaking VC and soon due to engine vibration, they start magically coming unloose! Make sure you torque the bolts to 55 inch/lbs. -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

After all your tube seals are installed they should look like this. The first 3 seals took me an hour or so. I did not like the way the non OEM seals looked, so redid with OEM. Once you get the hang of it, it is very easy and should not take you more than 5 minutes for each seal. With a little practice, you too can become a pro! -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

Now is also the perfect time to replace your Oil Control Valves. They are located right above each cam gear. Cost about $90 each and the left and right sides are different in that the connectors are in different locations. There are also Oil Control Valve filters for each valve, but to replace these $6 filters, the bearing cap will need to be removed. It's just too much work and if you regularly change your oil and PCV valve, you should be fine. Again, like the half moons, you may want to reseal the bearing caps at 250K or so. First unplug the black connector. Using a 10mm socket, remove the bolt. To remove the valve from the housing, I used a big screwdriver and using a hammer and gently punched it out. Have a rag underneath as there will be some oil spilling from the valve. Be careful of the wiring that will be in the way of the connector, especially on the driver side. Notice that the new part has a different (improved?) design. The new design has a smaller hole at the end. Each valve will come with a rubber o-ring and is oiled from the factory. To install, just press the valve in and then torque the bolt to .66 ft/inches. Do NOT over torque these bolts or they will snap! Guess how I know? Like everything else in this engine bay, everything has been cooking for a long time, so things have become brittle and fragile. If you do happen to snap one of these, just buy an M6 hex bolt with a 1/4" washer and it will be a direct fit. I got my bolt at Autozone. To get a replacement bolt from Toyota is a 10 day special order wait. -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

To remove the spark plugs, all you need is a 16mm spark plug socket and a 6" extension. Take the spark plug completely off the threads and then to remove, use a rubber hose to pull it out. No need for pliers. This method works far better than the little rubber crap that is in the spark plug sockets. Those things are always popping out due to oil and never work for me. To install the spark plug, use the same rubber hose to start the thread. Don't overtighten the plugs. You will feel the washers beginning to crush, then do another turn or 2 and that will be enough. The service manual calls for 13ft/lbs for those wanting to torque correctly. Don't forget to gap the plugs to .43" -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

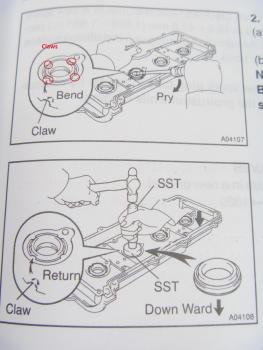

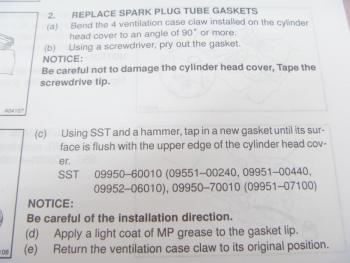

Now that the VC is removed, make sure everything is clean. First remove the gasket. Mine was not rock hard or brittle, but it was fairly hard and not soft and pliant like the new gasket. I used brake cleaner all throughout. Make sure the valley where the gasket goes is nice and clean. Remove any original FIPG with a razor blade. The FIPG will be around the half moons and the 2 corner spots where the cam housing is. Now you can remove and replace the spark plug tube seals. To remove, there are 4 claws that surround and go over the edge of each tube seal. Take a small screw driver and bend these up as much as you can up to 90 degrees. I first bent them up and then used some pliers to complete the 90 degrees. Then take a nice big flat tipped screwdriver and wedge the tip under the seal and pry up. It will be awkward and difficult at first but after the first couple, it becomes very easy. Wriggle it around and soon they will pop out. The rubber on mine was hard and brittle. Basically, the seal has a metal skeleton and does not flex. The inner part that fits over the tubes are flexible. Be careful not to gouge the VC metal. I had ordered some Beck/Arnley seals and although they are made in Japan, there is a clear difference from OEM. I decided to go with OEM as it is a better design. The OEM seals come pre oiled so no need to apply MP grease on the inner lip. The pic of the OEM is on the right. The ingenious part about these seals is that it has a secondary pooling area to catch oil before it can drip into the spark plug tube. Basically, if the seal fails and oil gets beyond the seal, then before it can drip into the seal, there is some space for oil to pool. You will have to see the actual seal to see what I mean. It's hard to explain in words. Then, clean the tube seal housing of all oil and debris using brake cleaner. To install the seal, I found it easiest by first taking the seal and pressing down with both thumbs. Make note of which side is up with your old seals as a reference. Let one side go in a little further at first. Then, using a hammer, just pound the seals in but be careful not to hit the claws and try not to damage the rubber. After the seals are in, tap the claws back into their original positions with a hammer. Or if you don't feel comfortable with the hammer approach, you can go to Harbor Freight and buy their Transmission Stop Off tool for $6. It fits the diameter of the seal perfectly. The fourth pics with the old seal bent is not the correct way to remove the seal and you will end up scratching up the walls of the housing. In the beginning, I wedged a screwdriver on the outer part of the seal. Don't do this. It is much easier prying from the inner part. Instead, with the inside of the VC facing you, take a large screwdriver and place underneath the seal. Then pry upwards. Or you can do it with the outside of the VC facing you, take a screwdriver and using a hammer pound it down and out. Again just be careful not to gouge the metal. -

1998-2000 Valve Cover Gasket Replacement

richardkwon replied to richardkwon's topic in 90 - 00 Lexus LS400

Attached are some pics of the LH VC. Notice all the gunk, carbon and caked on oil that has hardened into a nice crust. Took me a couple of hours to scrap it all off using a gasket scraper, small flat tipped screwdriver and whatever else that works. I don't think it's really worth the time to scrape this junk off but I like my stuff to be clean. Be careful when scraping the inside edges where the flat plate meets the sides of the VC. The metal board actually covers a cardboard like material underneath and about a 1/4 mm extends out and you can gouge it/rip it. The passenger side VC was surprisingly very clean and had some cake right where the PCV hose area is. Also attached is a pic of the RH torn PCV hose. It's hard as a rock and with the crack, not doing it's job. I had a number of hoses that were hard and cracked and that probably explains my recent imperfect idle as of late. If you don't want to shell out the money for an OEM hose, you can use a 90 degree fuel hose and cut to fit. My spark plugs were all dry and there was no oil leakage. However, I noticed on one spark plug tube seal that oil had made it past the seal and probably in another 5K to 10K miles would have started to leak into the spark plug hole. My recommendation: always replace the spark plug tube seals! It is not that difficult of a job but it is tedious as hell. I messed up on 3 non OEM seals until I finally got the hang of it. And now I could do these in my sleep.