azmalu

Regular Member-

Posts

114 -

Joined

-

Last visited

Profile Information

-

Lexus Model

es300

azmalu's Achievements

-

Power Steering, A/c, Alt Issues

azmalu replied to jc8587's topic in 93 - 05 Lexus GS300 / GS400 / GS430

harmonic balancer/ crankshaft pulley can grind wrong after high mileage or accident. that caused similar issue for me where steering right after turning car on was rough ac light would flash radio flickered then all of a suddent it all stopped working. -

How Can You Tell If U Need To Change Trans Fluid?

azmalu replied to vroom8's topic in 90 - 00 Lexus LS400

so for the non diy'ers like me that are considering a flush I have come across two options: http://www.gadgetonline.com/TransFlush.htm Cooler Line Flush The first type of flush machine connects into the transmission cooler lines. BG makes this kind and here is how it works. The line going from the transmission to the transmission cooler is disconnected and connected to the machine line in. The line out from the machine carrying new fluid is connected to the line going to the cooler. There is a chamber on the machine that has a diaphragm in it. The top part of the chamber above the diaphragm is filed with new fluid. The engine is started which turns the torque converter and the input shaft on the transmission. The input shaft turns the transmission pump and it makes hydraulic pressure. This causes fluid to flow through the cooler line. As fluid leaves the cooler line it enters the chamber on the flush machine. As the old fluid side of the diaphragm fills it pushes the diaphragm up and forces new fresh fluid into the transmission. After a while the old fluid is collected in the machine and it is replaced by new fluid. Now the transmission has been flushed. Really pretty simple. As you can see the machine cause no pressure and all fluid transfer is done by the transmission�s own pump. Pump Inlet Flush This kind attaches to the pump intake after the pan and filter is removed. This machine only supplies fresh new fluid to the pump intake and as the fluid passes through the transmission it dumps out to a collection tray and never goes back through for a second pass. All of the old fluid and crud is GONE and replace with fresh new fluid. After the service a new filter is installed, the pan replaced and then it is topped off with new fluid to the proper level on the dipstick. This process takes a total of 20 quarts of fluid to flush out 15 quarts of old fluid, replaces the fluid, and gives the mechanic the opportunity to look in the pan for anything unusual that would indicate a pending failure. Most local shops aamco brake masters midas etc use the cheaper cooler line flush option but always say they replace 99% of fluid. That sounds great but if they are not removing pan how do they get rid of metal sediments gunk etc.? Any thoughts? My car is at 100k . I think previous driver was very gently but I have had it for about 10k with constant stop and go traffic that is why I am concerned. I know doing flush can sometimes make things worse so maybe the less intense may be the better option. Please advise. Update: went to aamco..... Said they wont flush it. suppossedly has some internal problems. same issue we all describe about jerking between 1st and 2nd. told him not worried went on my way. still would like to find a shop to flush it. He said it was a quart low so debating on whether to fluid and some lucas...any thoughts? -

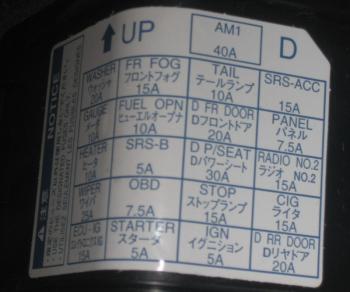

I have similar issue. Lights in ashtray turn on but actual plug doesnt work. Problem happenned after I had car audio shop wire up sub. funny thing is they installed relay swtich and they say now that it went bad. Something is fishy I will check panel on driver side. If cig light fuse is bad what else would have stopped working?

-

sakatj...the ebay link didnt work...What was in it? I'm around that 110k mark and am thinking about doing basic tune up things now. tran flush ,plugs, allignment...did all pads and turned rotors, synthetic tranny fluid? oem plugs are they denso platinum? car holds 6 qts motor oil right?

-

How Can You Tell If U Need To Change Trans Fluid?

azmalu replied to vroom8's topic in 90 - 00 Lexus LS400

so for the non diy'ers like me that are considering a flush I have come across two options: http://www.gadgetonline.com/TransFlush.htm Cooler Line Flush The first type of flush machine connects into the transmission cooler lines. BG makes this kind and here is how it works. The line going from the transmission to the transmission cooler is disconnected and connected to the machine line in. The line out from the machine carrying new fluid is connected to the line going to the cooler. There is a chamber on the machine that has a diaphragm in it. The top part of the chamber above the diaphragm is filed with new fluid. The engine is started which turns the torque converter and the input shaft on the transmission. The input shaft turns the transmission pump and it makes hydraulic pressure. This causes fluid to flow through the cooler line. As fluid leaves the cooler line it enters the chamber on the flush machine. As the old fluid side of the diaphragm fills it pushes the diaphragm up and forces new fresh fluid into the transmission. After a while the old fluid is collected in the machine and it is replaced by new fluid. Now the transmission has been flushed. Really pretty simple. As you can see the machine cause no pressure and all fluid transfer is done by the transmission�s own pump. Pump Inlet Flush This kind attaches to the pump intake after the pan and filter is removed. This machine only supplies fresh new fluid to the pump intake and as the fluid passes through the transmission it dumps out to a collection tray and never goes back through for a second pass. All of the old fluid and crud is GONE and replace with fresh new fluid. After the service a new filter is installed, the pan replaced and then it is topped off with new fluid to the proper level on the dipstick. This process takes a total of 20 quarts of fluid to flush out 15 quarts of old fluid, replaces the fluid, and gives the mechanic the opportunity to look in the pan for anything unusual that would indicate a pending failure. Most local shops aamco brake masters midas etc use the cheaper cooler line flush option but always say they replace 99% of fluid. That sounds great but if they are not removing pan how do they get rid of metal sediments gunk etc.? Any thoughts? My car is at 100k . I think previous driver was very gently but I have had it for about 10k with constant stop and go traffic that is why I am concerned. I know doing flush can sometimes make things worse so maybe the less intense may be the better option. Please advise. -

you went with: rotora rotors and hawk pads changed to synthetic fluid and g stop brake lines. Rears are all oem. .....So for stopping power is that why you chose oem for rears? What is bbk and supra front? Oem is semi metallic not ceramic like you said "if u do oem rotors or oem style rotors use the ceramic like they tell you to" What does changing brake lines do? So I guess some of it made sense but not really...will you clarify the things above...... not necessarily. i went with rotora rotors and some hawks pads, synthetic fluid and some g-stop brake lines all the way around (rears are oem factory pads/ oem factory rotors).....was just a personal choice. didnt matter to me what they were made out of, was for stopping power for my choice. if i ever get some extra $$ i'll do a bbk front and rear or a supra front . if u do oem rotors or oem style rotors use the ceramic like they tell you to. if u just driving on street some aftermarket pads/rotors are fine and do the brake lines while your at in in my opinion. i still feel hung over from this last weekend so i dunno if im making sense to you

-

Squeeking That Stops When I Apply The Brakes

azmalu replied to SlaveToFaith's topic in 93 - 05 Lexus GS300 / GS400 / GS430

I have the same issue. I think it is rear break pads and rotors. Just had fronts replaced and turned rotors. Those clips are annoying. I will confirm whether it is rear pads and rotors or clips up front. Same exact issue you described. -

It seems everyone is buying aftermarket rotors but trying to match oem pads? Does that mean most of yall prefer semi metallic to ceramic?

-

Factory Specs For Amp And Sub

azmalu replied to azmalu's topic in 93 - 05 Lexus GS300 / GS400 / GS430

okay determined factory 10 is a 2ohm sub. power handling unknown . factory amp power unknown. pulled from tundra forum thread by gs300 user : First, sit in the back seat and grab the front of the seat from underneath, lift until it pops out and remove the seat bottom. Now you see 7 bolts that hold the vertical back seat. Some are 12 mm others are 14 mm. Unscrew them all. Remove the head rests. Now lift the leather flaps under the headrests and unscrew the two 12 mm screws there. Move the vertical seat forward ( keep seat belts attached to the deck.at the top ). Now you can lift the rear deck and unscrew the existing sub. To install the new one ( with different bolt pattern ) you might have to use some plywood to trace the pattern of new sub and securely bolt it on said plywood. Use some foam gasket material between sub and wood to eliminate vibrations. Now check out the screw pattern in the deck and use the same bolts to install your plywood with new sub on it into existing spot. Again, use foam gasket material to dampen potential vibrations. -

Hi Guys, Havent found the specs for the factory amp power and sub ohm load. Crutchfield wasnt help. I will be building a ported box and having a few more inches for height would be nice. That is why I want to repalce factory sub with something that is more shallow than what we have now(4.5 inch depth. A lot of times factory systems run on 8 ohm load.

-

1998 Gs 300 Afermarket Grille And Hid Kits

azmalu replied to Blingologist's topic in 93 - 05 Lexus GS300 / GS400 / GS430

will someone post a picture of their grille after they did the grille mod? -

Portable Gps Mounting For A 99 Gs300

azmalu replied to uvadonkey's topic in 92 - 06 Lexus ES250/300/330

Not to sound cheeky but try the gs forum.... -

Hey guy I went and paid 12 bucks for a knob at local dealer that guy said was right fit. I know its not. It is a smaller knob and does not even cover the whole opening. Does anyone know the actual model no. for the non nak. stereo's in a 96 es. My 94 was Pioneer but I remember reading somewhere that this is a Fujitsu Ten. Still need model no. to try and order button directly from manufacturer. Please advise.

-

Looking For Car Audio Help On Lex Metra Kit Door Mods Es Owner New Ls

azmalu replied to azmalu's topic in 90 - 00 Lexus LS400

the mounting depth and mod work involved for 6.5 will be a lot of work and i dont know if it woudl be worth it. My first suggestiosn sell those buy same model if you like the sound 5.25" should cost you less than what you made when you sell your 6.5's lexls.com has diy instructions to get from factory 4 to 5.25 but 4 to 6 is big jump... -

great writeup: http://www.cureline.net/lex/howtos/howto_hood_shocks.htm